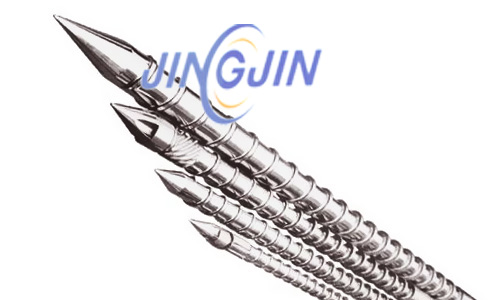

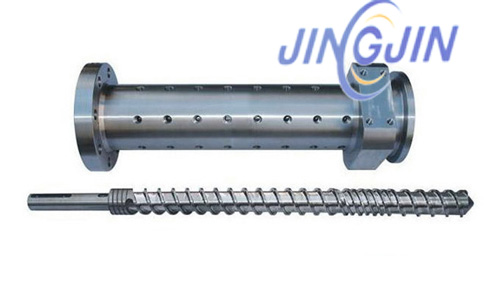

Tekli Vida

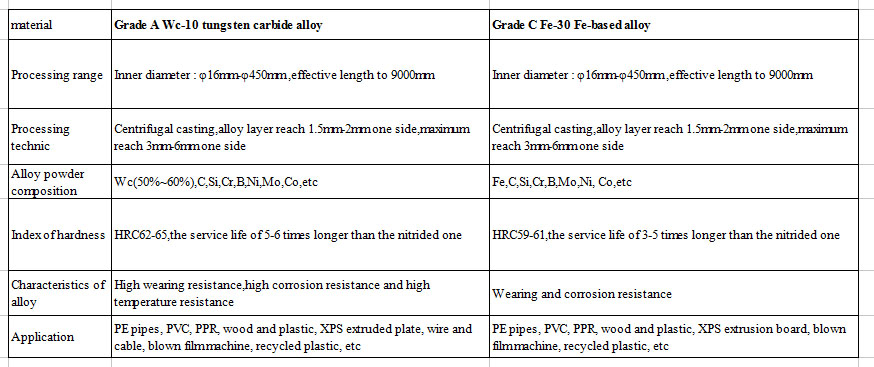

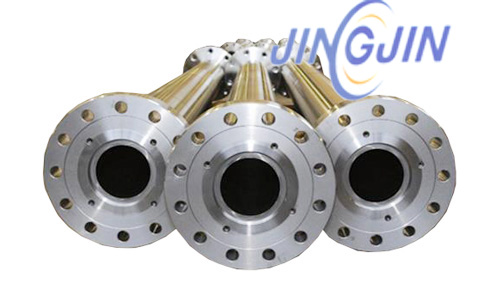

Bimetallic barrel for extrusion machine

Screw diameter: Ф20-Ф220

Mould clamping force: 100KN-35000KN

Shot weight:30-30000G

Screw can be mated with different heads of screw.

Cyclinder can be mated with differernt sprinkler heads.

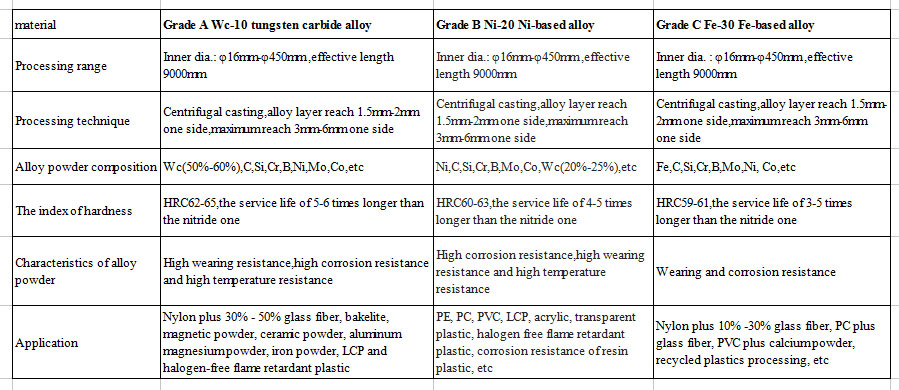

Technical Parameter:

Hardness After Hardening & Tempering:HB280-320

Nitrided hardness: 950-1100HV

Nitrided layer depth:0.50-0.80mm

Nitrided brittleness: ≤2 level

Surface roughness: Ra 0.4μm

Linearity of screw: 0.015mm/m

Bimetallic layer depth: ≥3mm

Bimetallic hardness: HRC60-72

Hard-chrome plating hardness after nitriding: ≥950HV

Chrome-plating layer depth: 0.025~0.10mm

Product classification:

According to different ingredents and products the screw can be chosen: general type, pin type, barrier type, separation type, and gas-exhausting/

vented type, etc.Technical Parameter:

Production use: Injection molding machinery / Bakelite machinery / injection molding machinery / Bakelite machinery / extrusion machinery / blowing machinery / blown film machinery / granulator machinery / extrusion machinery / pipe machinery / sheet machinery / wire and cable machinery

Effective length: 12000mm

Nitriding depth: 0.4mm-0.7mm

Nitriding hardness: HRC55 ° -58 °

Straightness: 0.015mm-1000mm

Scope: ordinary plastic, PP, PC, PE, ABS, AS, PS, PVC, PMMA, etc.

L/D ratio:15-55

Technical Parameter:

Hardness After Hardening & Tempering:HB280-320

Nitride hardness: 950-1100HV

Nitride layer depth:0.50-0.80mm

Nitride brittleness: Less than 2 level

Surface roughness: Ra 0.4μm

Linearity of screw: 0.015mm/m

Bimetallic layer depth: ≥3mm

Bimetallic hardness: HRC60-72

Hard-chrome plating hardness after nitriding: ≥950HV

Chrome-plating layer depth: 0.025~0.10mm

Product classification:

According to different ingredents and products the screw can be chosen: general type, pin type, barrier type, separation type, and gas-exhausting/vented type, etc.

Cold/Heat Feed Screw Specification: Ø65mm~Ø650mm

Technical Parameter:

Hardness After Hardening & Tempering:HB280-320

Nitride hardness: 950-1100HV

Nitride layer depth:0.50-0.80mm

Nitride brittleness: Less than 2 level

Surface roughness: Ra 0.4μm

Linearity of screw: 0.015mm/m

Bimetallic layer depth: ≥3mm

Bimetallic hardness: HRC60-72

Hard-chrome plating hardness after nitriding: ≥950HV

Chrome-plating layer depth: 0.025~0.10mm

Çiftli Vida

Refer to the following is small part of screw and the max part will be designed according to the compression ratio: Ф35/75,Ф40/83,Ф45/90-99,Ф48/112-117,Ф50/105-110,Ф51/105-120,Ф55/110-125,Ф58/125, Ф60/125-129,Ф65/120-132,Ф68/147,Ф70/Ф50,Ф74/156-162,Ф80/143-156-162,Ф86/177,Ф92/184-188

Techniccal parameter:

1.Raw Meaterial:38CrMoAlA

2.Hardness after Hardening & Tempering: HB240-280

3 Nitriding treatment,Surface hardness:HV1030-1080

4 Nitriding depth:0.5-0.7mm

5. Surface roughness: Ra0.4um

6.Fragility of Nitriding: ≤grade 2

7.Straightness: 0.015mm/m

8.Hardness of Bimetallic :HRC55°-68°

9.Depth of Bimetallic: >2mm

10.Chromium-plating hardness:HV≥900

11.Chromium-plating Depth:0.025-0.10mm

Scope of application :

PVCwood-plastic., PE wood-plastic,,Super high polymer board,1/2 high Calcium buckle,50-400 high Calcium pipe,50-300 high Calcium Profile,soft PVC sheet, PVCfoaming boardetc.

PP、PE、ABS、PVC,raw material pelletzing,plastic pipe,plastic profile,and plastic sheet etc.

Ф60/2, Ф65/2, Ф70/2, Ф72/2, Ф75/2, Ф80/2, Ф85/2, Ф90/2, Ф93/2, Ф100/2, Ф105/2, Ф110/2, Ф115/2, Ф120/2, Ф125/2, Ф130/2, Ф140/2, Ф150/2, Ф160/2, Ф170/2, Ф180/2, Ф190/2, Ф200/2, Ф250/2,

Techniccal parameter:

1.Raw Meaterial:38CrMoAlA

2.Hardness after Hardening & Tempering: HB240-280

3 Nitriding treatment,Surface hardness:HV1030-1080

4 Nitriding depth:0.5-0.7mm

5. Surface roughness: Ra0.4um

6.Fragility of Nitriding: ≤grade 2

7.Straightness: 0.015mm/m

8.Hardness of Bimetallic :HRC55°-68°

9.Depth of Bimetallic: >2mm

10.Chromium-plating hardness:HV≥900

11.Chromium-plating Depth:0.025-0.10mm

Scope of application :

PVCwood-plastic., PE wood-plastic,,Super high polymer board,1/2 high Calcium buckle,50-400 high Calcium pipe,50-300 high Calcium Profile,soft PVC sheet, PVCfoaming boardetc.

PP、PE、ABS、PVC,raw material pelletzing,plastic pipe,plastic profile,and plastic sheet etc.

原材料raw material 成品处理要求

The finished product processing equirements

38CrMoAlA,SACM645,42CrMo 渗氮处理Nitriding treatment

42CrMo,AISI 4140 电镀硬铬层Electroplating Hard chrome layer

4Cr5MoSiV1,SKD-61,SKD-11 喷涂双金属合金层再渗氮处理

Spraying bimetal alloy layer and nitriding treatment

HPM38,SI36,SUS440,Cr18MoV 不锈【铁】钢, 高频淬火stainless steel high frequency quenching

GHII3 高温工作自然硬化nature hard after high temperature